An unprecedented micro 3D printing method now allows scientists to manufacture tiny, complex metal components in a direct and simple process. The FluidFM technology used in this procedure was designed by ETH Zurich scientists years ago for biological research. Now it has successfully been enhanced for usage in a completely different area of application. The ETH spin-off Cytosurge AG is now further developing this new 3D printing process for commercial use to be made available to interested customers in various markets shortly.

At present, there is no satisfactory solution available on the market to produce metallic micro- and nano-structures in a direct 3D print process. With most existing techniques overhanging structures can only be realized in an indirect process requiring multiple production steps. Moreover, alternative technologies are often based on laser assisted sintering of highly reactive micro metal particles, a process which calls for the highest safety standards and therefore comprises a major cost factor in such systems.

Scientists at ETH Zurich have now developed a completely new 3D micro printing process. With this procedure it is now possible to produce tiny – also partly overhanging - structures in a single, straightforward production step. In the near future this technique could for example be used to manufacture complex watch components or micro-instruments for minimally invasive surgery. Dr. Pascal Behr, co-founder and CEO of Cytosurge states: “The newly developed 3D printing method is suitable for applications in various markets. Presently we see potential applications especially in the watch- and semiconductor industry as well as in medical device sector.” With current trends leading towards continuing miniaturization and customized mass production as well as the aspiration for ever shorter development and production cycles, the new 3D print technology based on FluidFM comes at exactly the right time. “It offers our customers interesting growth potential and possibilities to increase efficiency.”

The central component of FluidFM technology is a moveable micropipette mounted on a cantilever leaf-spring, which can be positioned extremely precisely. In contrast to normal pipettes, FluidFM technology measures and controls the forces which the pipette exerts on a surface with in real-time and with high precision. The technology is well-established in the life science sector and provides Cytosurge with a solid base for further growth in various markets in which microscopic metal structures are of importance.

Currently, Cytosurge is evolving existing products in order to make the new 3D print technology available to interested research teams in the industry as well as at universities as soon as possible. Furthermore, the company is planning the development of an independent product line for industrial applications. In this context Cytosurge takes a great interest in cooperating with established industrial partners as well as potential investors to accelerate the necessary developments.

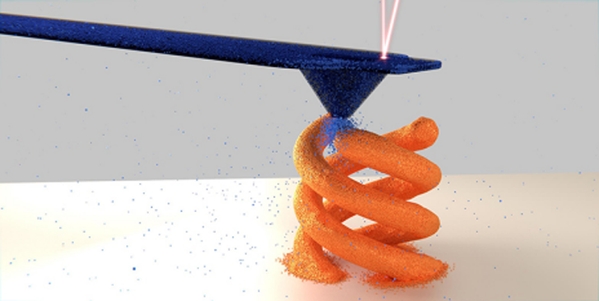

FluidFM based 3D printing - Electrochemical reactions at the pipette tip

In this newly developed system a copper sulfate solution flows through the pipette with an opening of only 300 nanometers. Using an electrode, the scientists cause a chemical reaction under the pipette aperture: The copper sulfate emerging from the pipette reacts to form solid copper, which starts to grow on a base plate of gold following the movements of the pipette.

“This method can be used to print not only copper but also other metals,” says Tomaso Zambelli, associate lecturer and group leader at the Laboratory of Biosensors and Bioelectronics at ETH Zurich. “FluidFM may even be suitable for 3D printing with polymers and composite materials.

A significant advantage of the new method over other 3D micro printing processes is that the forces acting on the tip of the pipette can be measured. “We can use this signal as feedback. Unlike other 3D printing systems, ours can detect which areas of the object have already been printed,” says Luca Hirt, ETH doctoral student and inventor of the new 3D printing technique. “This will make it easier to further automate and scale the printing process.”

About Cytosurge AG

Cytosurge AG was founded as an ETH Zurich spin-off in 2009. The company successfully develops and distributes scientific measuring instruments and robotic systems based on the patented FluidFM technology. In 2012 the company was awarded the renowned “ZKB Pionierpreis Technopark” for the development and commercial launch of FluidFM. Cytosurge products enable versatile applications in the areas of material science, physics and biology. Especially in the emerging field of single cell analysis, FluidFM offers considerable advantages compared to traditional procedures. A passionate team of specialists with backgrounds in various disciplines strives for the best solution for their clients. With its unique and innovative offerings, Cytosurge helps its customers to shape tomorrow’s cutting-edge research in various branches.

(Photo: ETH Zurich / Alain Reiser)

(Press release)

Please login or sign up to comment.

Commenting guidelines