Unisieve offers a high-precision membrane solution that decarbonizes heavily emitting industries by drastically reducing heating and cooling in chemicals and improving carbon capture. The startup has secured $5.5m in a seed funding round to pilot and expand production capacities. With their participation, Amadeus APEX Technology Fund has made its first investment in Switzerland.

The oversubscribed funding round saw participation from a venture capital consortium including the Amadeus APEX Technology Fund, Wingman Ventures, Ciech Ventures and Zürcher Kantonalbank. The funds will allow Unisieve to accelerate its development while expanding its production capacity.

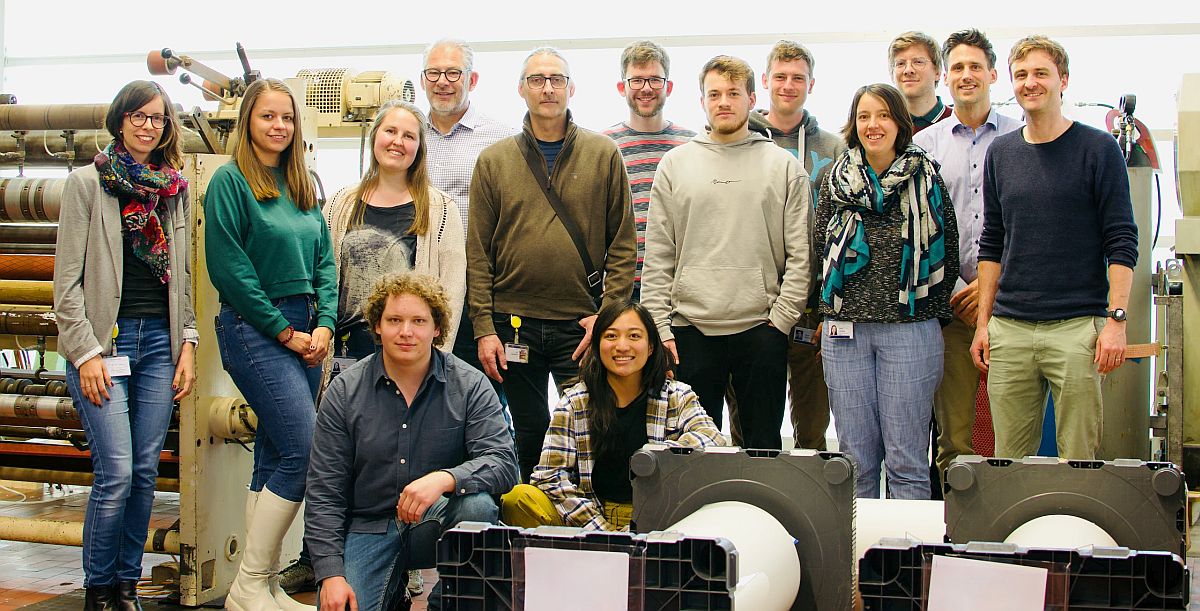

Wolfgang Neubert, General Partner at the Amadeus APEX Technology Fund, commented: “UniSieve is our first industrial technology investment in Switzerland. We were impressed by the team’s ability to bring their academic thesis to life and make it commercially viable and scalable. It has the potential to be hugely impactful for the world. We look forward to supporting the team on their journey.”

Founded in 2018, UniSieve is dedicated to solving the heavy industries’ energy drain challenge to help them get closer to Net-Zero goals. Today, 10-15% of the world’s energy consumption accounts for separation and purification, a key process step for most industries. Heavy industries have still failed to create energy efficiencies in their legacy, highly energy-intensive assets that are worth billions of dollars. For example, in chemical plants, a major energy drain is the chain of separation and purification steps because this still depends on energy-intensive thermal processes.

The Zurich-based startup developed membranes-based separation solutions that can separate chemicals, energy carriers, or CO2 from flue gas based on size exclusion, without heat or cold. The solution bypasses the need for heating or cooling through sieving membranes that can reduce the energy needed for separating and purifying molecules by up to 90%.

“Our solution is addressing a major emissions cause and its potential for energy and emission reduction is significant for our planet”, says Samuel Hess, CEO and co-founder of Unisieve. “In essence, we say stop boiling and start sieving to end energy-intensive distillation. The concept of sieving works as simple as a coffee filter holding back the coffee powder from an espresso. However, it gets a little tricky when separating chemicals that vary in size by a fraction of an angstrom only (1 angstrom equals one-tenth of a nanometer). To do so, the sieve must be extremely narrow and precise. The UniSieve membrane is a structure made of a highly ordered network of porous crystals that generate in a repeating pattern, much like ancient Roman mosaics,” explains Samuel.

The company has completed pilot testing with industry leaders, demonstrating that the separation solution works. With a solution ready to be deployed, the startup has signed several contracts with others under negotiation to pilot the membranes in a variety of applications.

To this end, Uniseive has obtained Pre-seed funding from Wingman Ventures and several prestigious grants from the European Union, the Swiss government, and private foundations enabling them to prove the hypothesis of their scalable and affordable high-performing membranes.

(Press release/RAN)

Please login or sign up to comment.

Commenting guidelines