Apheros is developing a novel patent-pending technique for manufacturing metal foams to facilitate cooling. The technology has the potential to transform cooling technologies and pave the way to a more energy-efficient future.

The energy needed for the cooling of electronics has a significant environmental impact. It is estimated to account for 6% of global energy consumption by 2030. Cooling also represents a limiting factor in the performance of many applications, from batteries to chips and motors. The market for cooling solutions is valued at around USD 20 billion with a CAGR of 6.1%; however, metal foams are not yet established, as current manufacturing methods are costly and only viable for high-end, heat-exchanger applications. Zurich-based startup Apheros aims to change that.

Apheros has developed a new manufacturing method for metal foams with exceptional cooling properties. Their unique microstructure exhibits a surface area that is 100 to 1,000 times larger than that of existing metal foam products, allowing for the release of more heat and improving the performance of applications with a high thermal load.

Their 3D-printed metal foams also retain the basic properties of metal, such as excellent thermal and electrical conductivity and mechanical stability. Thanks to their light and ultra-porous properties, they are suitable for applications beyond cooling, such as filtration, catalysis, and energy storage.

Apheros is targeting engineering companies hoping to improve their cooling solutions. Currently, it is testing the solution in energy storage in collaboration with the Swiss Federal Laboratories for Materials Science & Technology (EMPA), the University of Berlin, and the Fraunhofer Institute for Manufacturing Technology & Advanced Materials (IFAM) in Dresden. The startup has also inked collaboration agreements with Maxon Motors to develop heat sinks for motors and the Boyd Corporation to establish proof of concept trials.

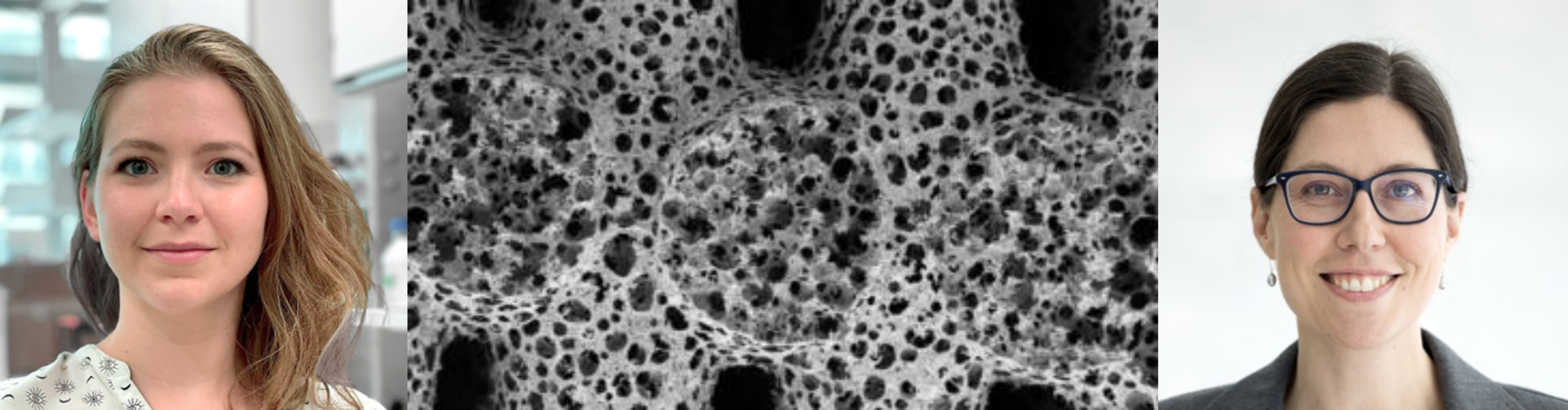

The startup will invest the CHF 150,000 awarded by Venture Kick to expand its client base and upscale its production process. Its team comprises Julia Carpenter, co-inventor of the technology; Gaëlle Andreatta, who accrued 15 years of experience in R&D at an Oxford spin-off and in the materials department at CSEM; and scientific advisor Prof. Dr. André R. Studart, head of the Complex Materials group at ETH.

(Press release/RAN)

Photo: Julia Carpenter and Gaëlle Andreatta

Please login or sign up to comment.

Commenting guidelines