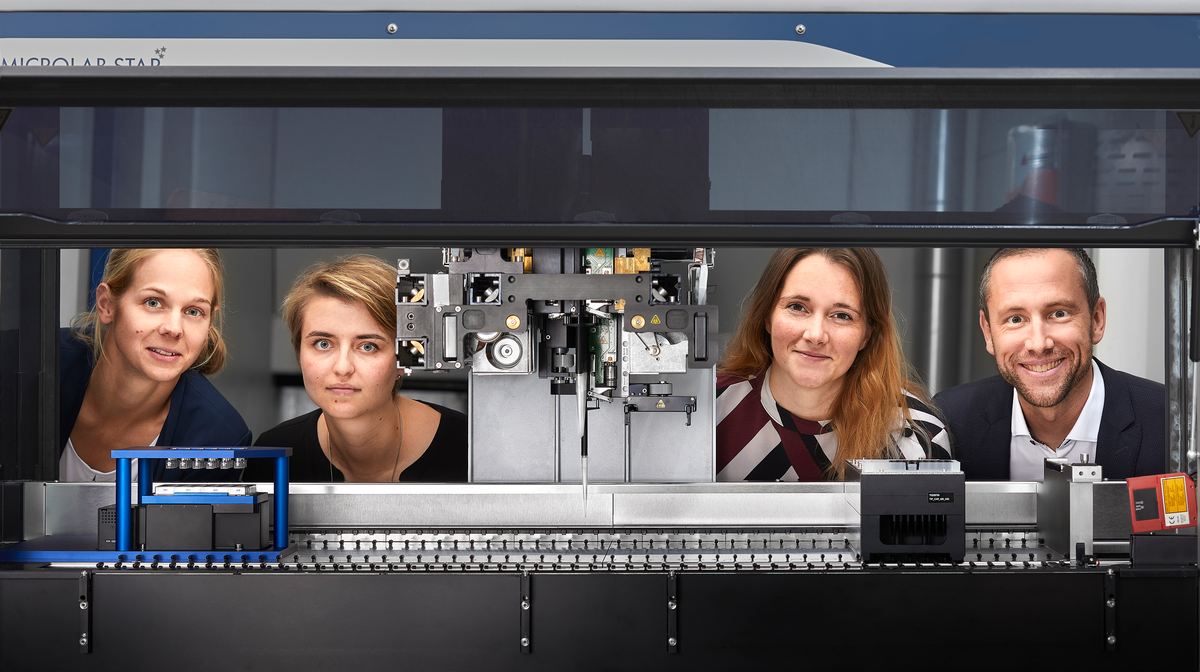

SUN bioscience launches its Gri3D platform which enables the large-scale, standardized, rapid, and reliable production of 3-D in vitro organoid cultures from patient stem cells. The large scale standardizing of organoids represents a key advancement toward personalizing medicine. The platform has been industrialized with CSEM technological support as part of an Innosuisse project.

Organoids play an essential role in the development of personalized medicine based on the patient’s genetic profile. Reproductions of human organs on a microscopic scale, they represent a solution of choice for drug testing. They also promise a better understanding of neurodegenerative diseases and cancers, paving the way for patient-specific drug screening. By offering the large-scale production of these mini organs SUN bioscience’s Gri3D platform takes a decisive step toward fully exploiting their potential.

Co-founder of the Swiss start-up, Sylke Hoehnel, explains the birth of this innovation: “As part of our research work at EPFL, we developed a new solution for culturing organoids from stem cells. Its innovative feature is in the U shape of the microwells in which the cells are grown in hydrogel. This difference allows the cells to self-organize and cluster in the desired 3-D formation.”

Creating an all-in-one platform for all organoid protocols

With the introduction of Gri3D, homogeneous populations of organoids from a specific patient can now be produced in a few days or weeks and even, for the first time, many months. Organoids such as the retina, intestine, brain, and pancreas have already been successfully produced and cultivated on the SUN bioscience platform.

Innosuisse project with CSEM

As part of an Innosuisse project, CSEM industrialized the production of the Gri3D platform. “The robot we developed succeeded in creating exactly the needed hydrogel microtopography in which the human stem cells can be seeded,” explains Gilles Weder, coordinator of CSEM’s applied biosciences team. “What was decisive was that we carefully analyzed and simplified the production process before moving on to the automation stage.” Nathalie Brandenberg, co-founder of SUN bioscience adds: “In addition to technical skills, CSEM had the advantage of being familiar with the required multidisciplinary approach and having solid experience in production process engineering,” notes Nathalie Brandenberg, co-founder of SUN bioscience. “And its researchers are used to supporting scientists in the industrialization of their innovations.”

Picture: From left to right: Nathalie Brandenberg (SB), Sarah Heub (CSEM), Sylke Hoehnel (SB), and Gilles Weder (CSEM), CSEM

Please login or sign up to comment.

Commenting guidelines