Known as 3D printing, additive manufacturing refers to the technology of creating three-dimensional parts by placing layers together. In this process, each layer bonds to the previous layer of molten or partially molten material. Digitally defined by computer-aided design (CAD) software, the layers cool and fuse together to form a three-dimensional object. Several types of materials can be used, such as metals, polymers and ceramics. Quality control of the parts produced is very important, particularly for metal parts which are often subject to critical mechanical stress. However, this is expensive, up to 40% of the total production cost, and is carried out off-line after manufacture. This also entails a high risk of not identifying all production defects.

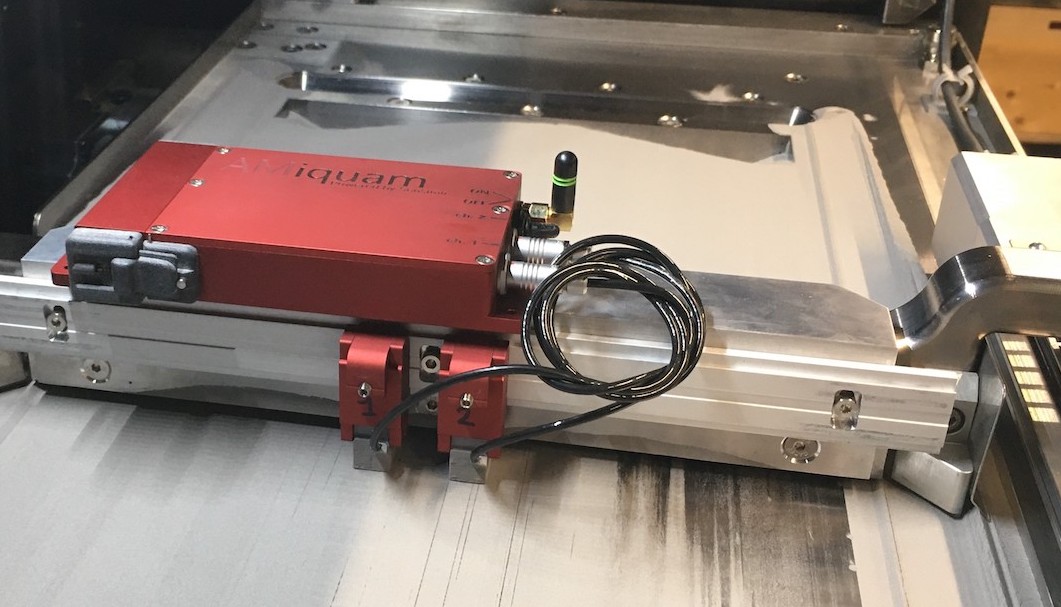

In order to reduce this cost and increase the quality of the final parts, it is therefore necessary to monitor them in real time, i.e. during manufacture and inside the machine. This is what AMiquam has developed thanks to an innovative technology based on non-destructive testing and electromagnetic response measurement. AMiquam’s approach is also highly innovative in that its system is independent of machine make or model. AMiquam’s device is indeed machine agnostic and totally energy independent. Everything is managed by an on-board battery and the measurements are transmitted wirelessly, making the system particularly portable. The start-up has in fact filed a patent in 2021 for its technology. With this major technological breakthrough, AMiquam enables its customers to reduce the costs and time required for part inspection. Its customers and partners already include major players in the aerospace, medical and even additive manufacturing machine manufacturers. In addition, to date, the team has secured the support of Venture Kick as well as PULSATE, a pan-European network aimed at democratising the adoption of additive manufacturing technology.

The Tech Seed loan will enable the startup to carry out several pilot projects in technical sectors such as aerospace or medtech, and thereby pursue the development of its products.

(Press release)

Please login or sign up to comment.

Commenting guidelines